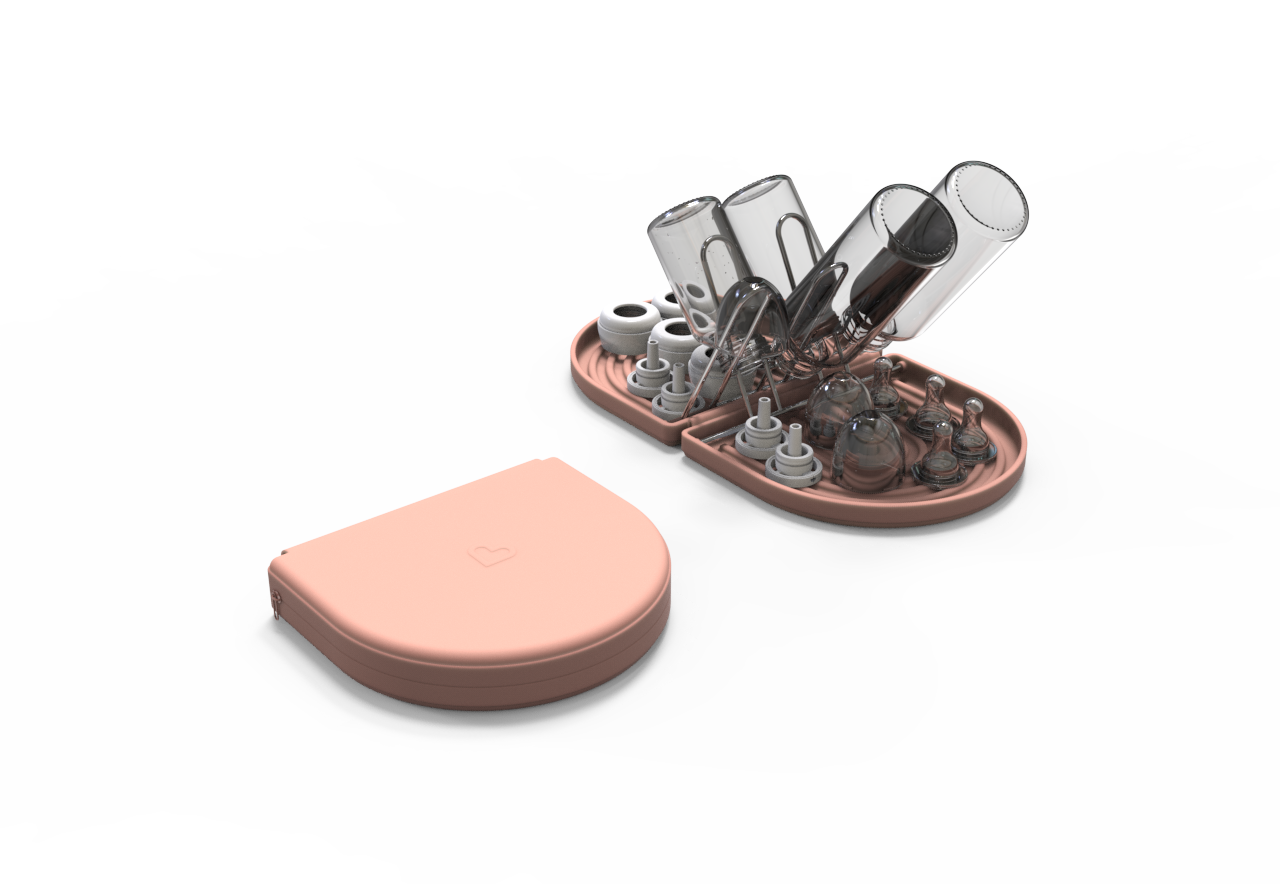

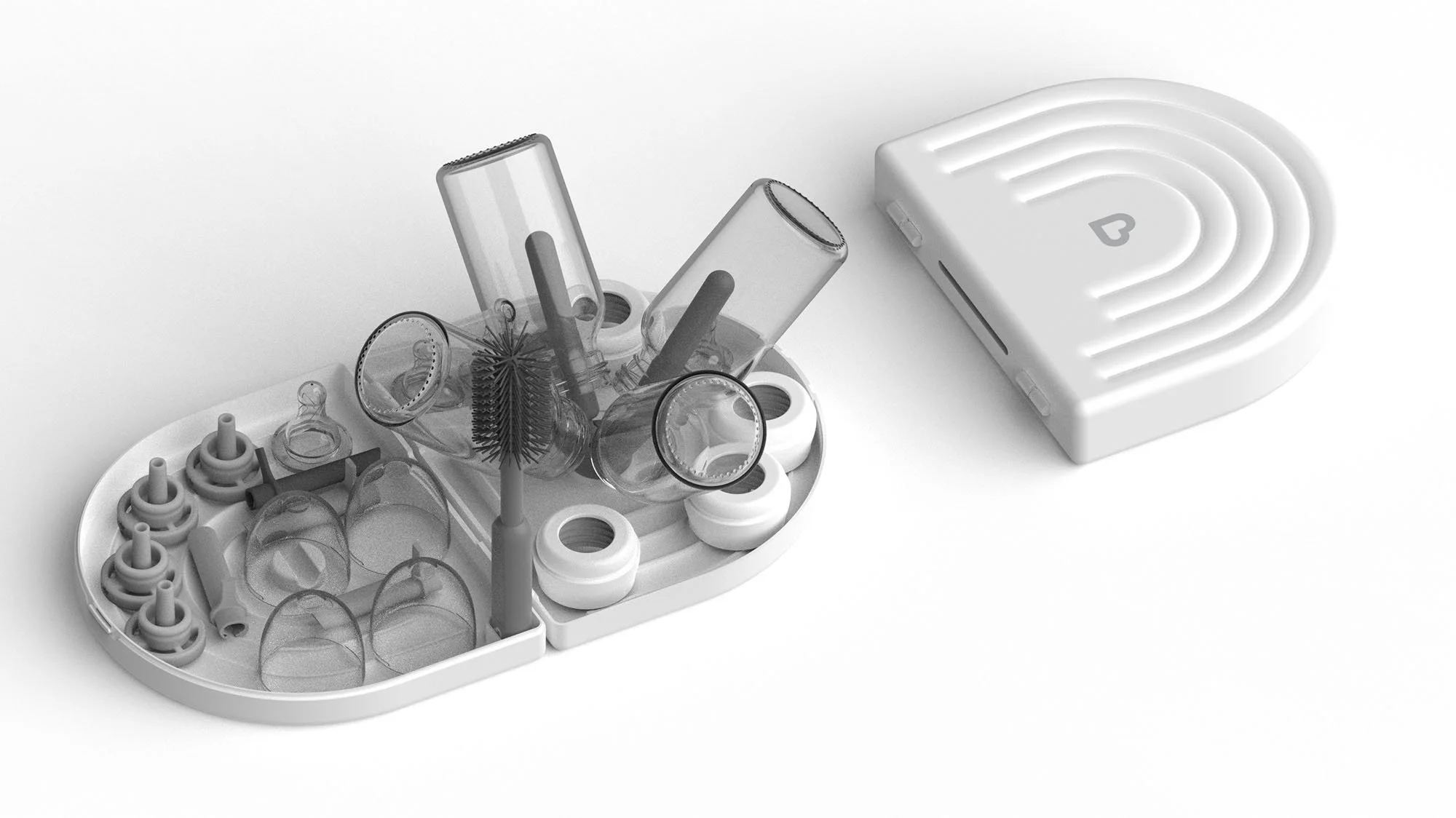

Bottle care doesn’t stop when you leave home. The Portable Drying Rack was designed as a compact travel companion that fits easily into a diaper bag and simplifies bottle care on the go.

The goal was to extend Munchkin’s drying rack category into travel with a solution that felt genuinely useful in a crowded market. Parents still need a clean, reliable way to dry bottles and accessories while away, yet most travel options feel awkward, fragile, or overpriced.

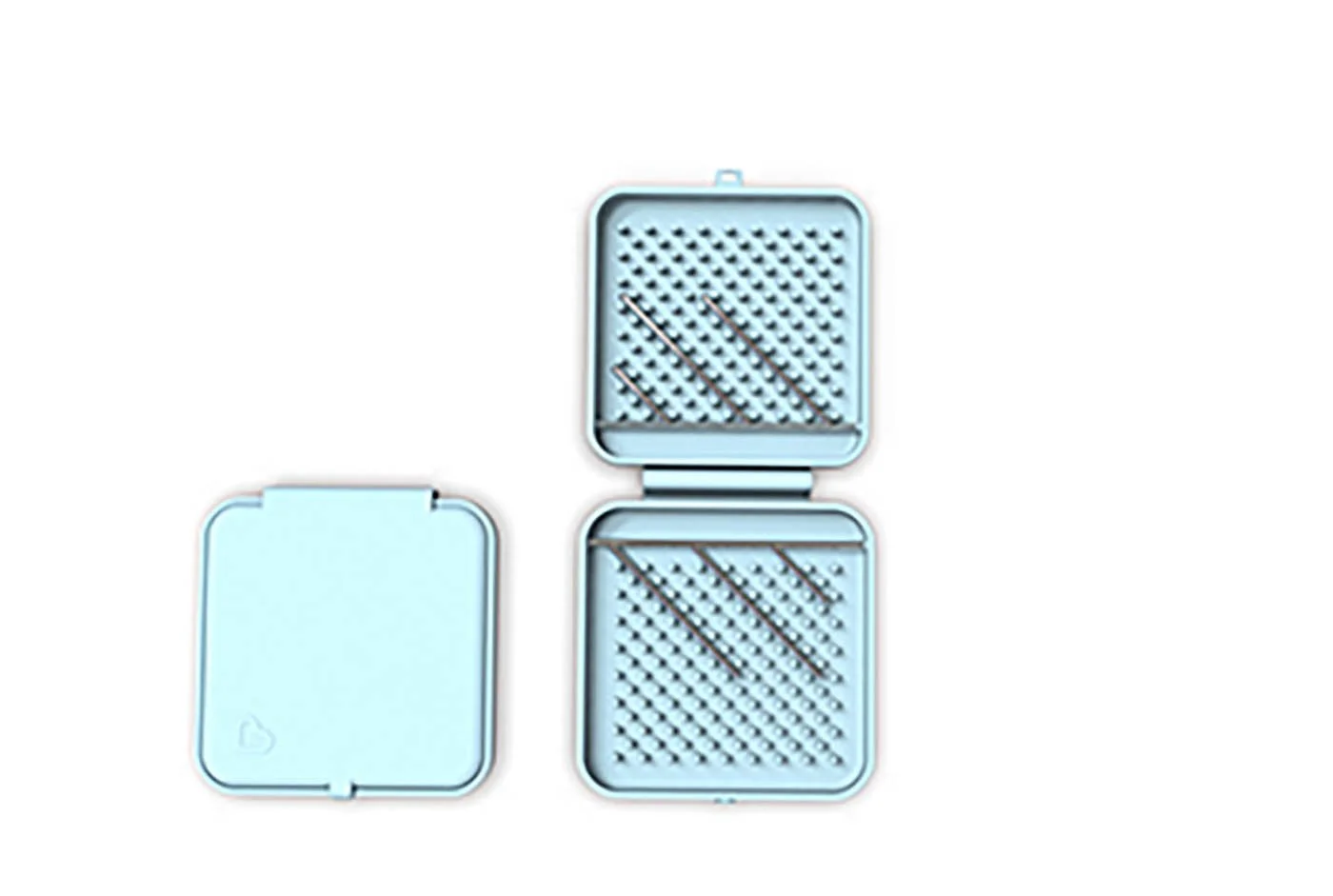

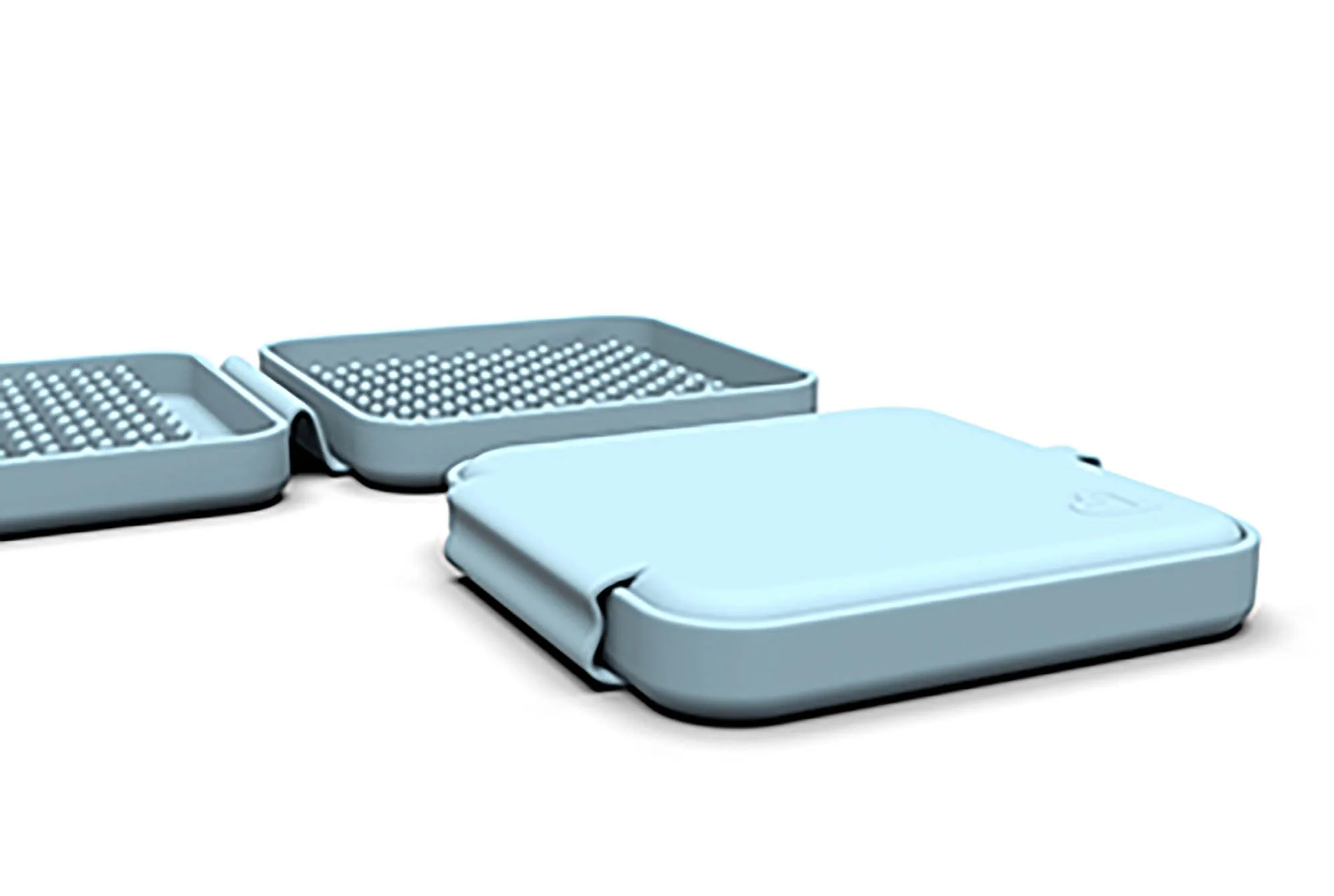

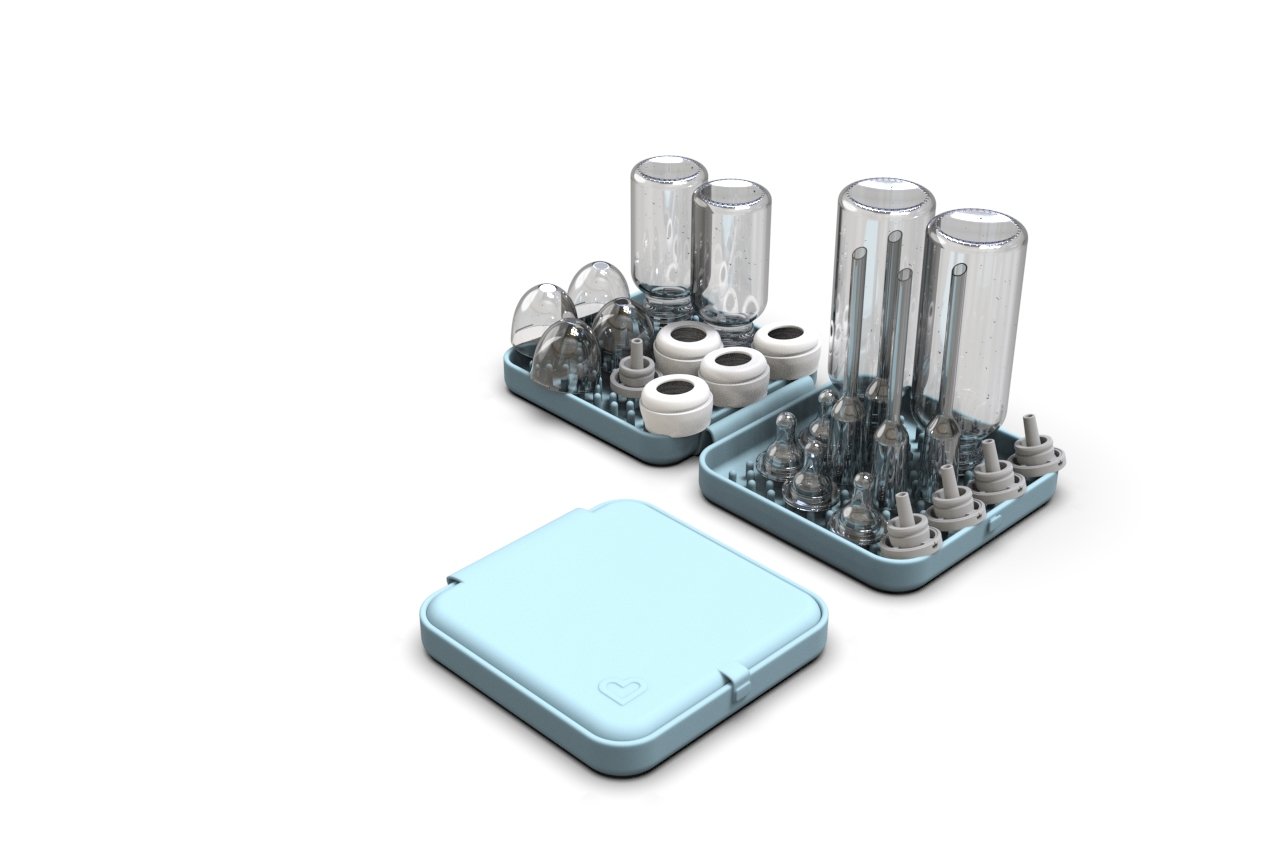

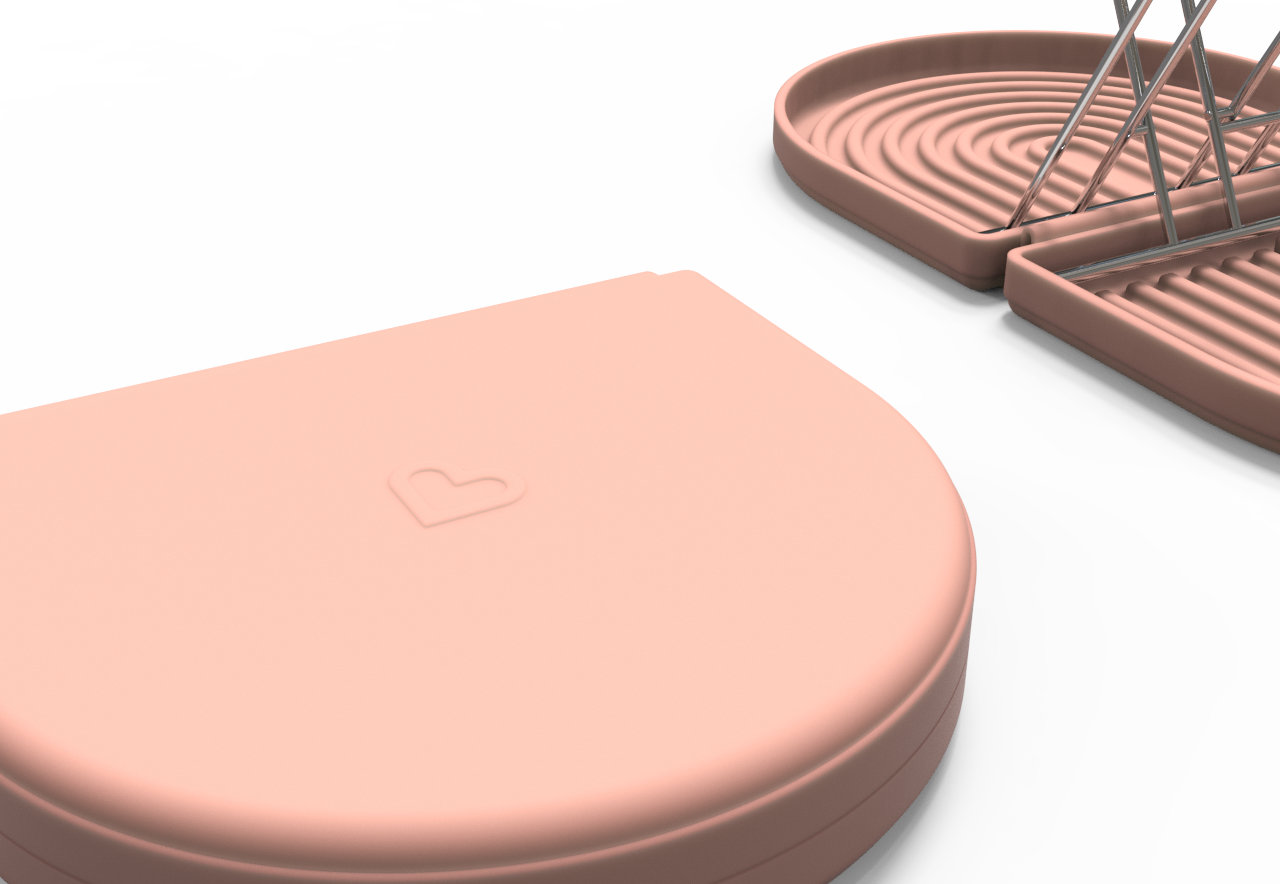

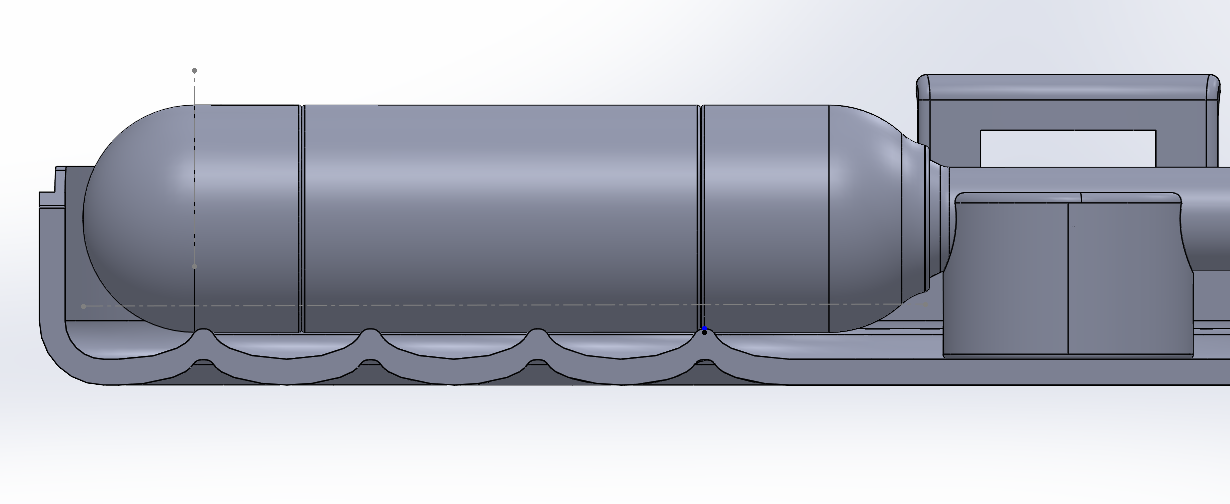

The final design features angled pegs for faster drying, dedicated space for small parts, and an integrated extendable brush. While early concepts explored silicone-based approaches, the product ultimately focused on a safe, durable construction that could meet cost targets without sacrificing quality.

This project began as a category extension for Munchkin. The goal was to bring bottle-care into travel within an already crowded market and strict cost constraints. Below are some of my intiial concepts.

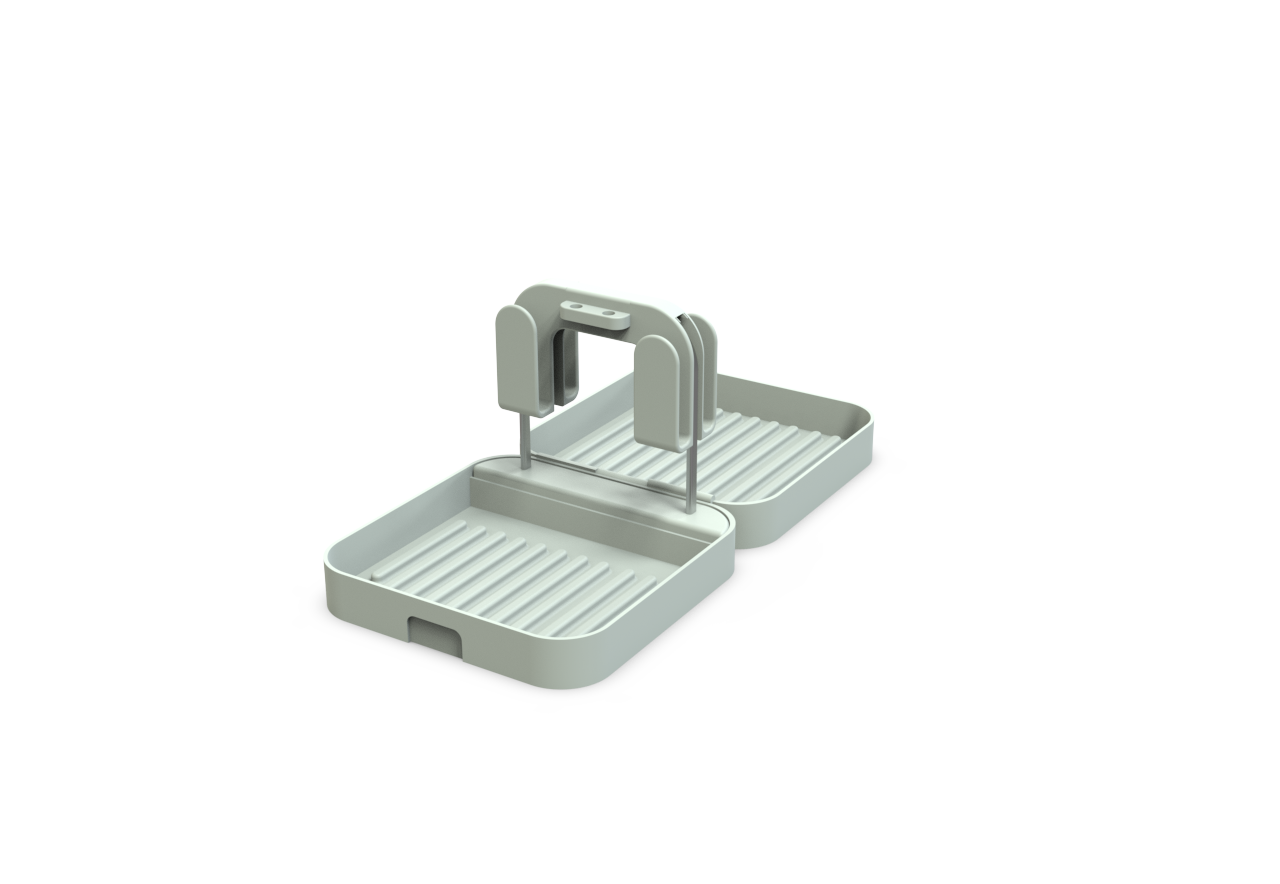

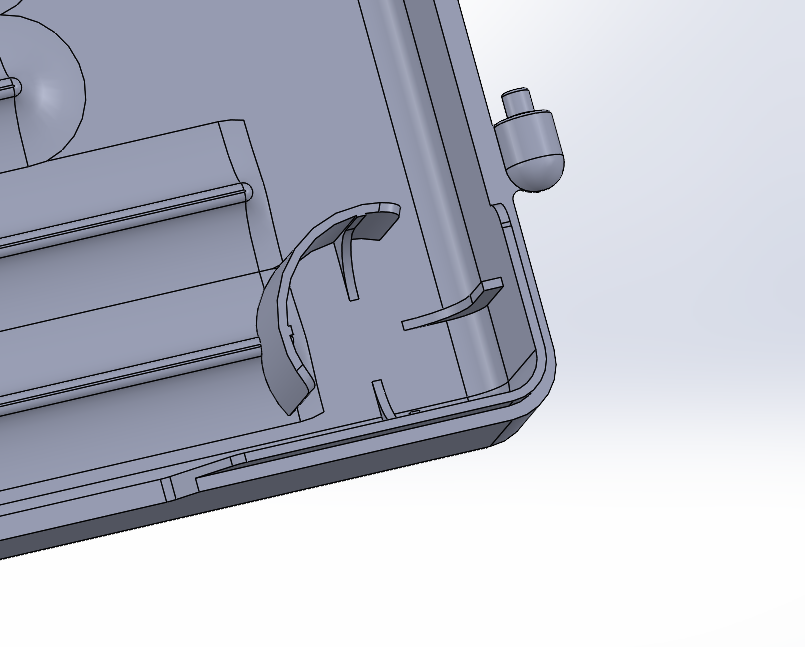

This concept explored a collapsible basin that doubled as a drying rack lid—allowing bottles to be washed and dried without a sink, while keeping the process contained and sterile. It was a smart, integrated solution. Ultimately, the team chose a safer direction.

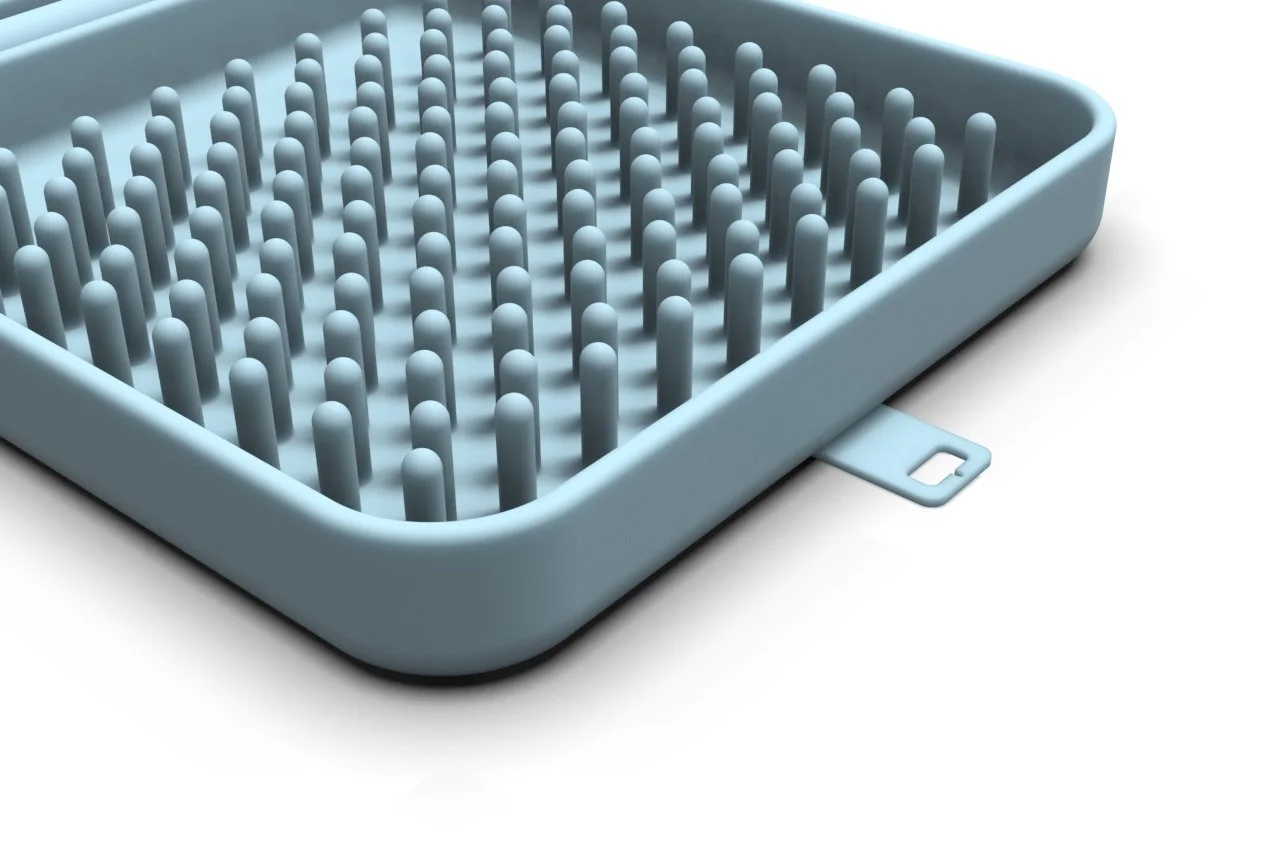

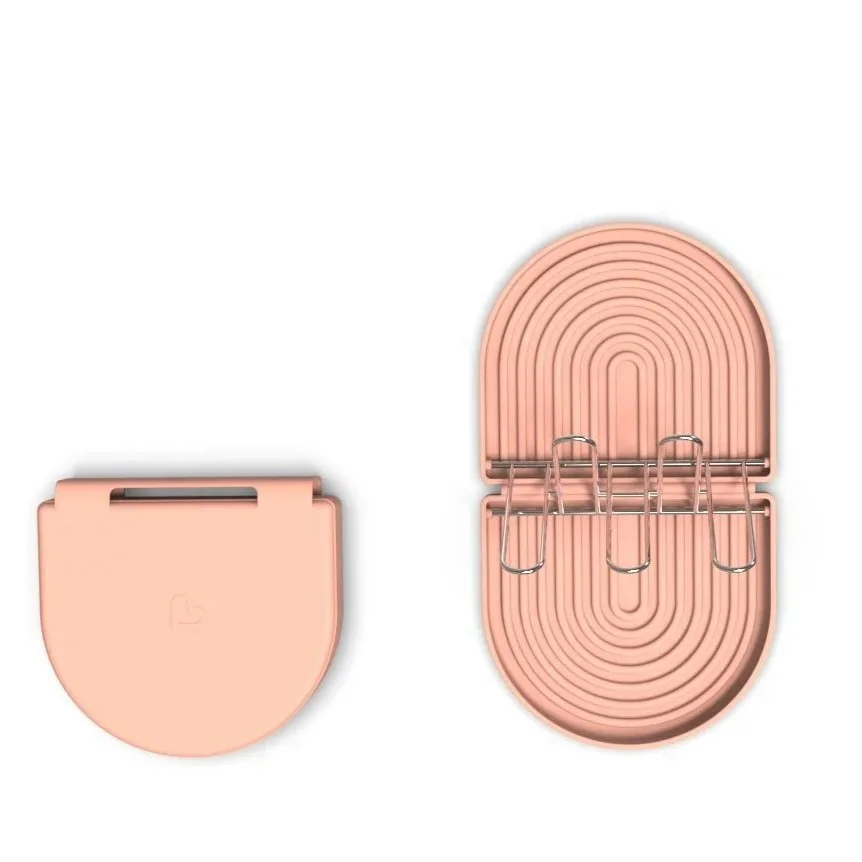

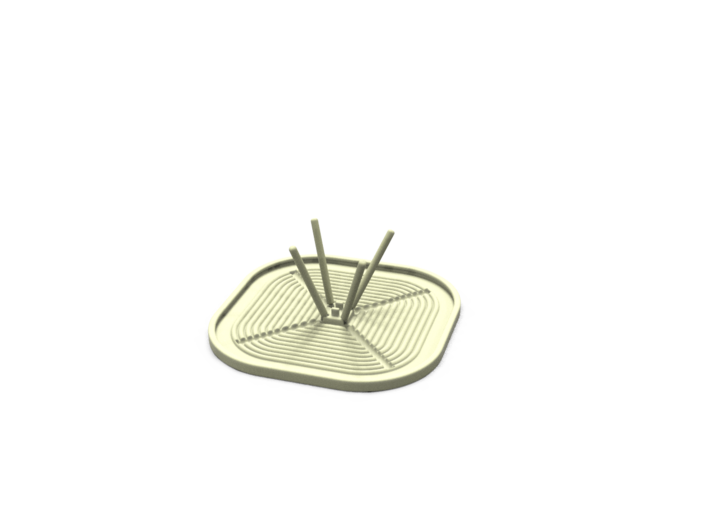

A simple trivet design I encountered mid-process became a key influence. What followed was a complete re-engineering of the idea.

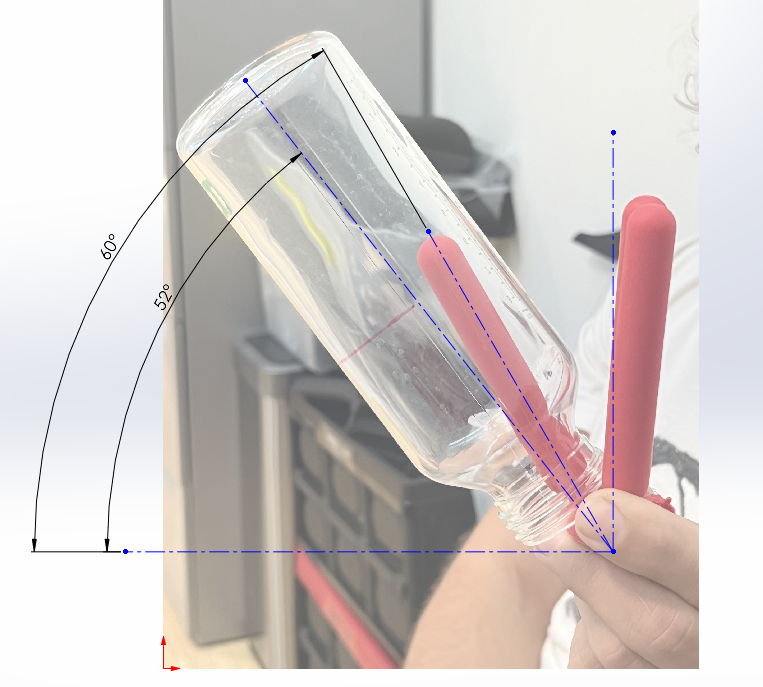

Through further user testing, we learned that parents typically travel with just one to three bottles. Designing around that reality allowed us to reduce the footprint dramatically and position the product as the most compact solution in its category.

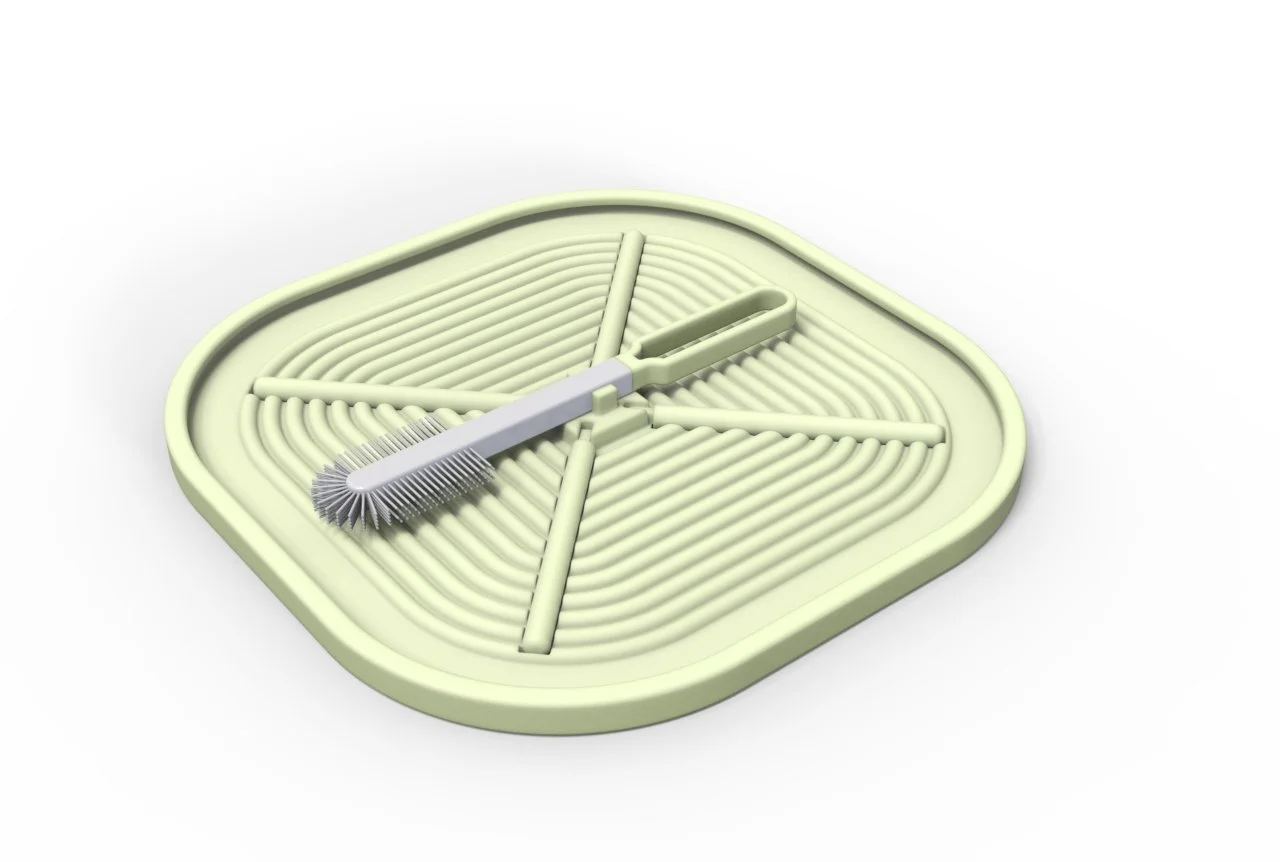

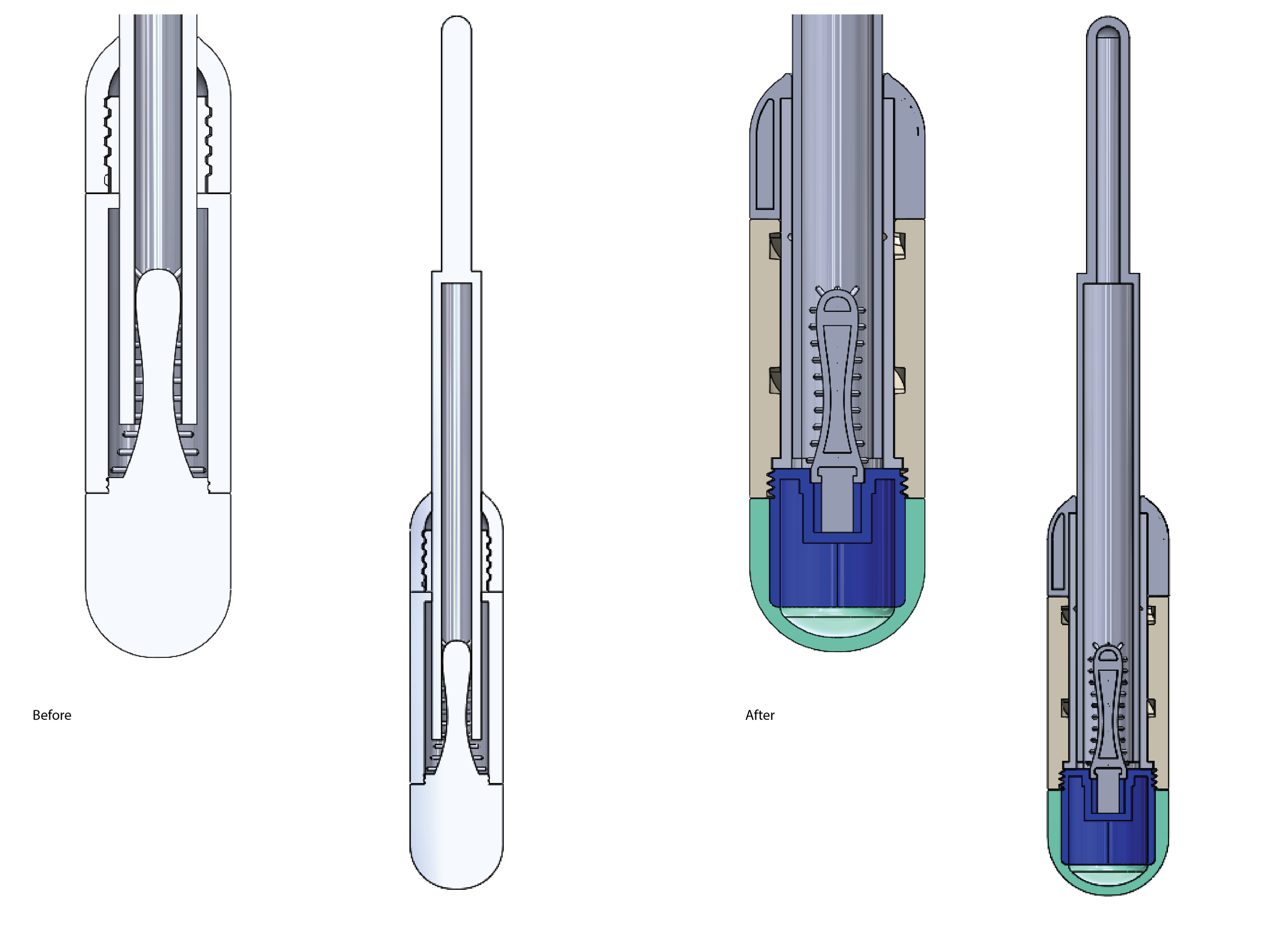

This is what I wanted our brush to look like. Nice and clean, mirroring the shape of the trivet.

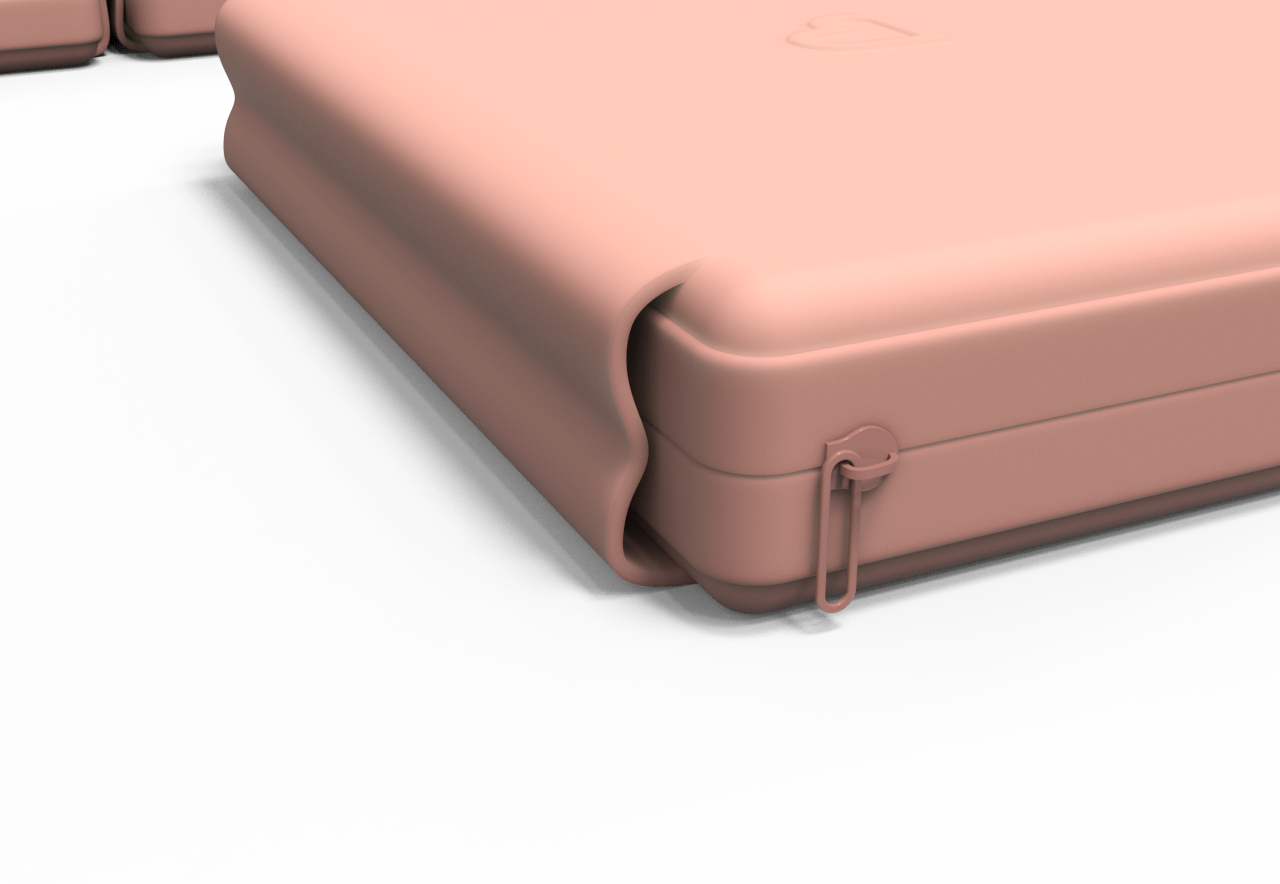

This is what the engineering team was able to produce. Not quite the same, is it? So, I had to compromise, which is a major part of design for manufacturing. However, I still feel my design was quite achievable.